Smart Manufacturing,

Real Results.

Every manufacturing company is losing money! GlobalReader’s OEE software collects real-time data to show where and how to improve.

No trial, no financial commitment! Sign in with Google or create a free account and you’ll be guided through with a quick tour.

"GlobalReader delivers as promised – data that enables data-driven decisions!"

Daiļrade Koks

Daiļrade Koks

Mudite Maido, Daiļrade Koks

Collect real-time data

Your subscription includes both hardware and software, which can be easily set up by you or with assistance from our technicians.

Identify bottlenecks and Improve OEE

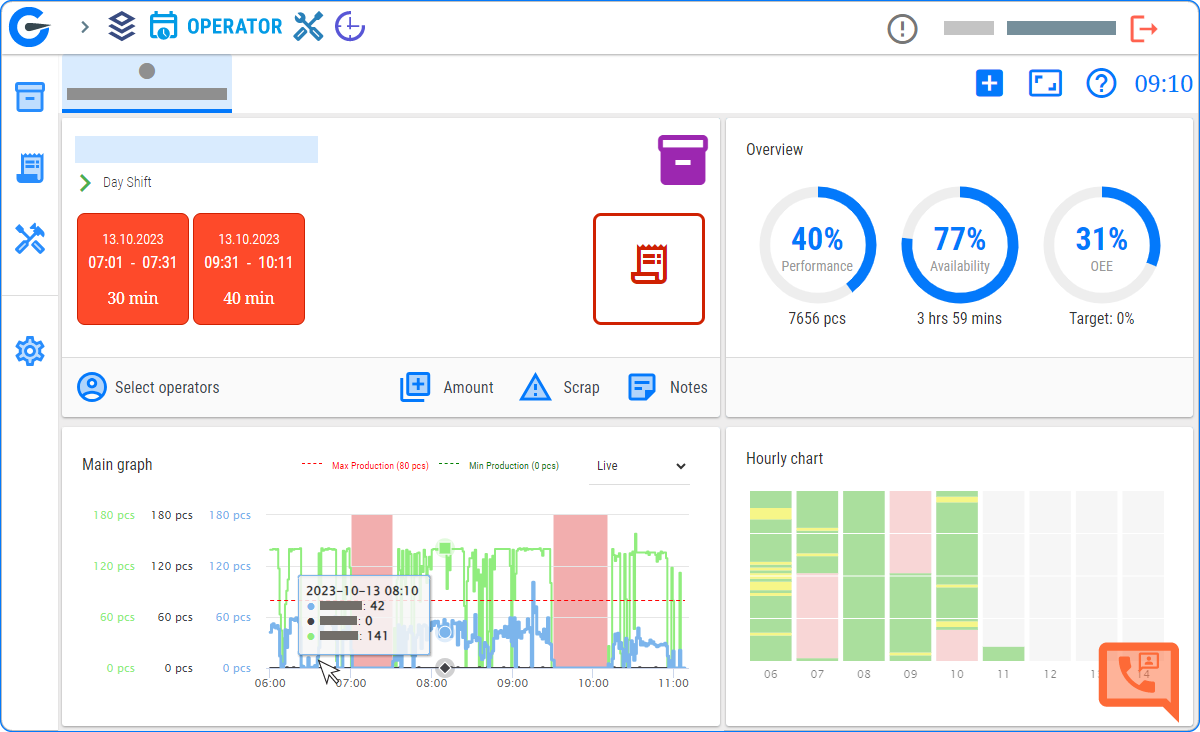

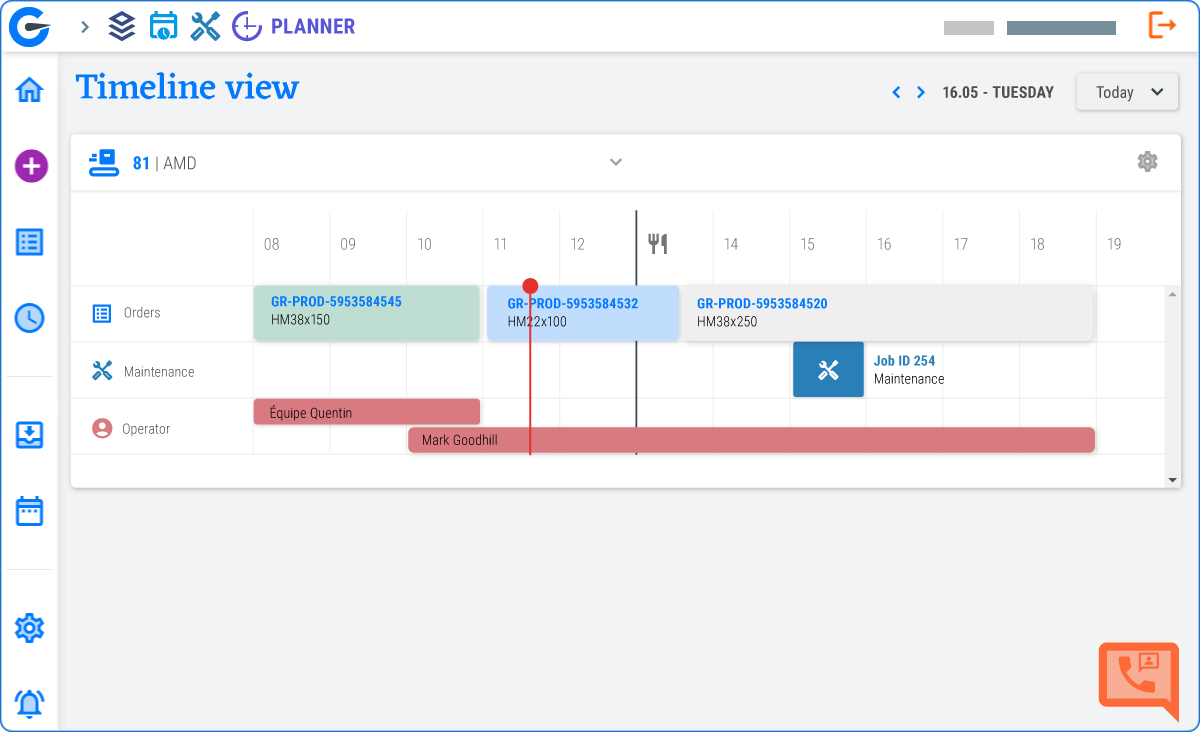

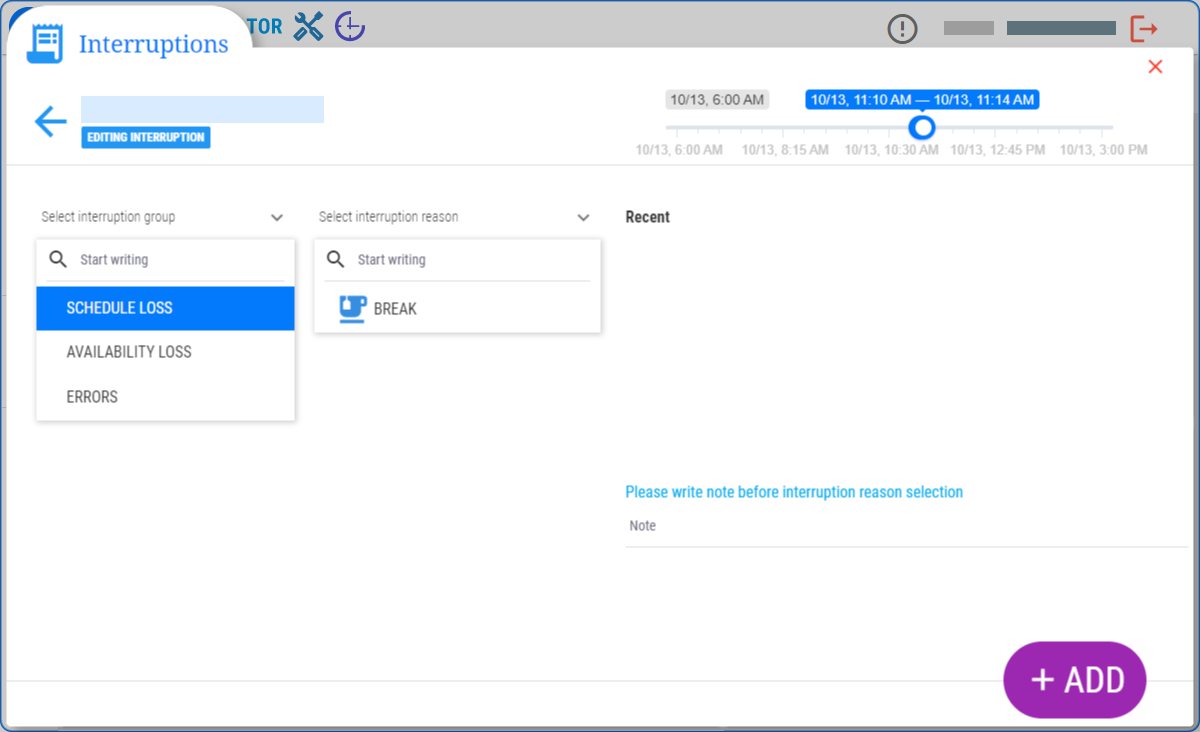

Monitor real-time production and take immediate action to enhance OEE. Later, analyse the data to understand discrepancies between actual performance and the production plan. GlobalReader OEE software collects and provides insights into these variations.

Customise

Explore GlobalReader array of extra features and add-ons designed for you. Enjoy custom reports, personalised production feedback, and tailored live views. Plus, seamless integration with your ERP systems.

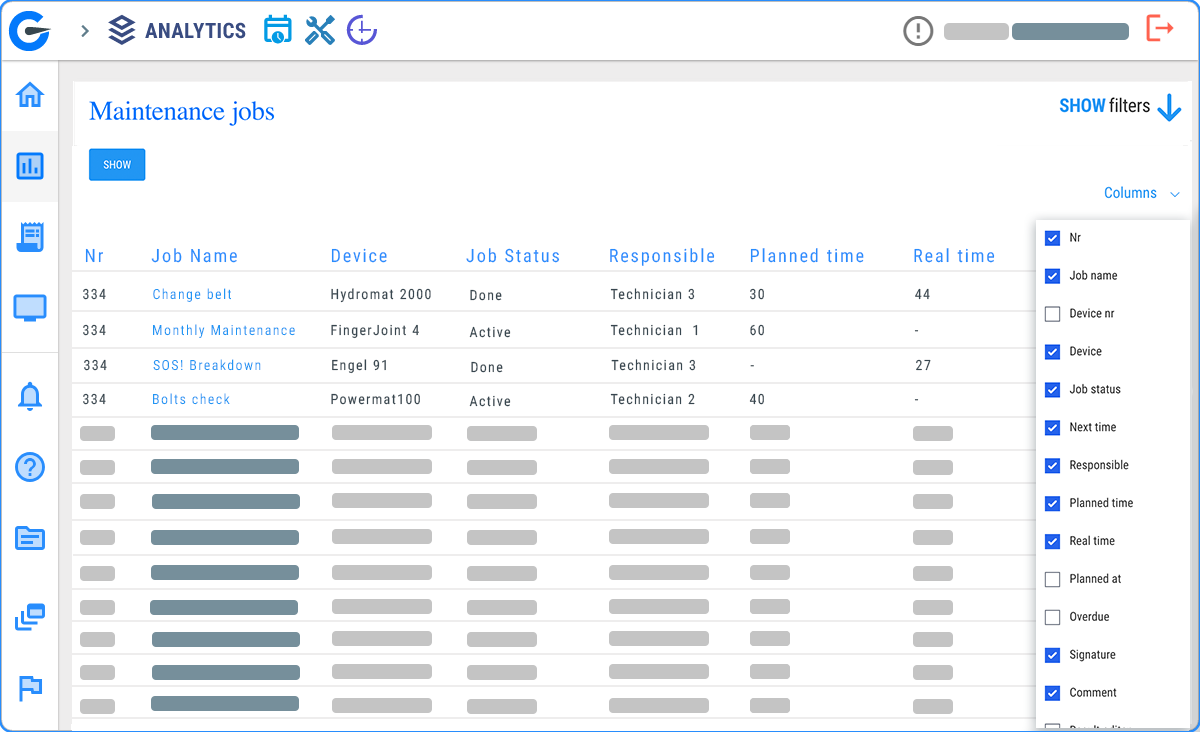

Analytics View

Maintenance View

Operator View

Timeline View

Interruptions

Main Graph

"With the use of GlobalReader monitoring equipment on different machines, we now have a better insight into the efficiency of the operation of these machines."

Alcantra

Alcantra

Production Manager, Taavi Palu. Oü Alcantra

Find out WHY you are losing money in production with our OEE/MES software.

All Manufacturing companies have some level of inefficiency and fail to fully utilize their potential! Globalreader offers an unparalleled solution aimed at enhancing the efficiency of manufacturing companies

No trial, no financial commitment!

Sign in with Google and you’ll be guided through with a quick tour.

Measure.

Analyse.

Improve.

-

Seamlessly capture metrics from your machinery for a clear, accurate picture of operations.

-

Turn raw data into actionable insights, enabling data-driven decision making.

-

Identify inefficiencies, reduce downtime, and enhance overall equipment effectiveness (OEE)

-

Provide real-time dashboards and tools for transparent communication across teams.

-

Anticipate issues before they occur, ensuring smoother, uninterrupted production.