Tracking a Performance Report will Enhance OEE

Operators play a pivotal role in maintaining and improving production efficiency, as their actions directly impact equipment availability, performance, and quality. By implementing advanced operator performance report tracking systems, manufacturers can identify inefficiencies, provide targeted training, and optimise workflows to boost OEE.

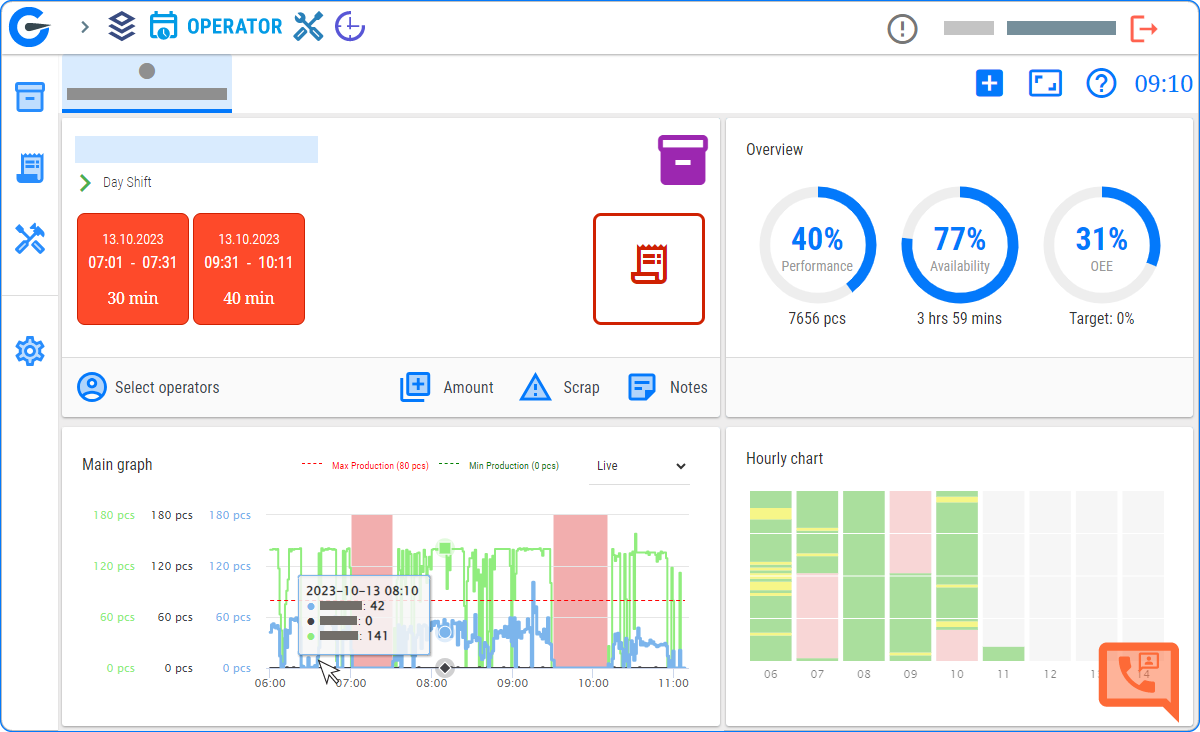

GlobalReader’s Operator tool offers comprehensive features for monitoring and analysing operator activities in real-time, helping to reduce errors, improve productivity, and ensure consistent quality. This article explores how tracking operator performance can lead to significant improvements in OEE by leveraging data-driven insights and proactive management strategies.

Downtime Analysis

Downtime is one of the most significant factors affecting OEE. It refers to periods when equipment is not operational and production is halted, leading to decreased availability and productivity. Downtime can be caused by various factors, including equipment failures, maintenance activities, changeovers, and operator errors. By analysing downtime, manufacturers can identify the root causes and implement strategies to minimise its occurrence.

Performance Report Tracking and Analysing Downtime with GlobalReader

GlobalReader’s Operator tool provides comprehensive downtime tracking capabilities. It captures detailed data on when and why downtime occurs, allowing manufacturers to analyse patterns and identify recurring issues. This real-time data collection helps in understanding the frequency, duration, and causes of downtime, providing a clear picture of areas that need improvement.

Benefits of Downtime Analysis:

Identifying Bottlenecks: Downtime analysis helps in pinpointing specific bottlenecks in the production process that cause delays. By addressing these bottlenecks, manufacturers can streamline operations and improve overall efficiency.

Reducing Unplanned Downtime: Real-time monitoring and analysis of downtime events enable proactive maintenance and quick resolution of issues, reducing unplanned downtime and keeping production on track.

Enhancing Operator Accountability: Tracking operator performance and downtime allows for better accountability and transparency. Operators are more likely to adhere to best practices and protocols when their activities are being monitored.

Improving Training Programs: Insights gained from downtime analysis or a performance report can be used to develop targeted training programs. By understanding common operator errors and inefficiencies, training can be tailored to address these specific issues.

Problems with Manual Downtime Analysis

Inaccuracy and Inconsistency:

One of the primary issues with manual downtime analysis is the inaccuracy and inconsistency of the data collected. When operators record downtime events manually, there is a high risk of human error. This can include incorrect logging of start and stop times, misclassification of downtime reasons, and failure to capture all relevant details.

Inconsistent data collection practices across different shifts or operators further exacerbate this problem, leading to unreliable data that is difficult to analyse effectively. Accurate downtime tracking is crucial for identifying patterns and implementing improvements, and manual methods often fall short of providing the necessary precision.Time-Consuming and Labor-Intensive

Manual downtime tracking is a labour-intensive process that consumes significant amounts of time and resources. Operators must take time away from their primary tasks to log downtime events, which can interrupt workflows and reduce overall productivity. Additionally, the process of compiling and analysing manual records is time-consuming and often requires dedicated personnel to sort through and interpret the data. This inefficiency can delay the identification of root causes and the implementation of corrective actions, ultimately hindering efforts to improve OEE.

Limited Data Utilisation

Another major drawback of doing downtime analysis and creating a performance report manually is the limited ability to utilise the data effectively. Manual records are often fragmented and lack the integration needed for comprehensive analysis. This makes it challenging to generate meaningful insights and visualise trends over time.

Without automated tools to aggregate and analyse data, manufacturers may miss critical opportunities for improvement. Advanced machine monitoring solutions, like Analytics and Maintenance, automate data collection and provide powerful analytics capabilities, enabling more effective and timely decision-making. These tools help manufacturers move beyond the limitations of manual tracking to achieve continuous improvement and enhanced OEE.

The Top Causes of Machine Downtime

Equipment Failures: One of the most significant causes of machine downtime is equipment failure. This can occur due to various reasons such as wear and tear, lack of maintenance, or unexpected malfunctions. When machinery breaks down, it not only halts production but also incurs additional costs for repairs and replacement parts. According to our experience, understanding and predicting these failures through data analysis can significantly reduce downtime by enabling proactive maintenance and timely interventions.

Implementing predictive maintenance strategies, as offered by GlobalReader, can help anticipate equipment failures and schedule maintenance before breakdowns occur, thereby minimising unplanned downtime.

Setup and Adjustments: Another common cause of downtime is the time spent on setup and adjustments. This includes activities such as machine changeovers, calibration, and tool changes. These processes are essential for maintaining product quality and consistency but can be time-consuming if not managed efficiently. Downtime due to setup and adjustments can be particularly problematic in industries with high product variability and frequent changeovers. By optimising setup procedures and using tools like GlobalReader planner, real-time monitoring and analytics, manufacturers can streamline these processes, reducing the time required for adjustments and keeping production running smoothly.

Implementing Continuous Improvement

Regularly reviewing any performance report and analysing downtime data is essential for continuous improvement and as a plus you will work towards green manufacturing. By setting benchmarks and tracking progress over time, manufacturers can measure the effectiveness of their downtime reduction strategies. GlobalReader’s comprehensive reporting tools allow for easy visualisation of downtime trends and the impact of implemented changes, ensuring that continuous improvement efforts are data-driven and effective. Becoming a Smart-Factory is the next step to efficiency and insight to the manufacturing process. Choose Globalreader and leverage operator tool today! Request a demo now.