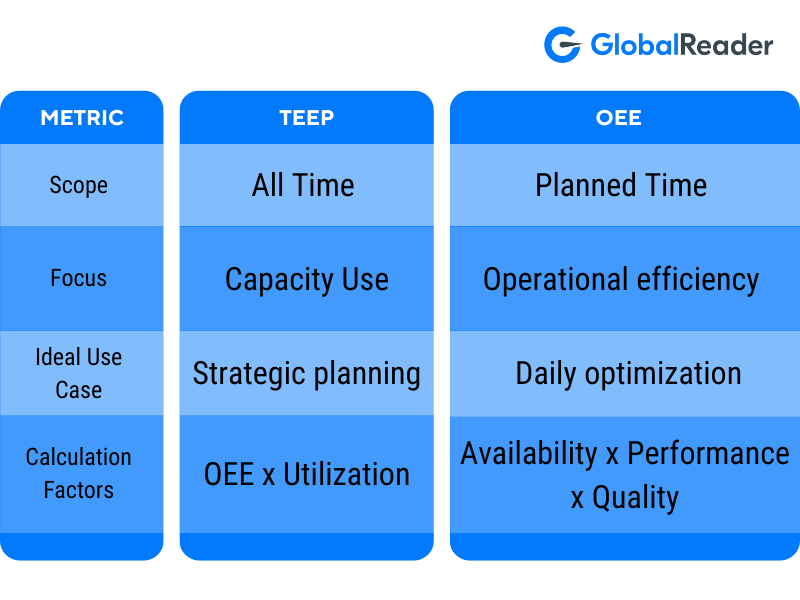

Get a comprehensive overview about OEE

Deep Dive Into Digitalisation

Everything about Lean Manufacturing

Read GlobalReader Case Studies about OEE

Everything about Data Analysis

Everything about TEEP

All GlobalReader Posts

5 Steps to Digitalisation: Push Your Manufacturing to Maximum Efficiency

In today’s fast-paced manufacturing world, inefficiency, sadly, is the norm, not the exception. All manufacturing companies are innefficient! From outdated equipment to manual processes, factories are losing valuable time and resources every day. This constant struggle with inefficiencies leads to increased costs, reduced productivity, and lost opportunities. Find out the GlobalReader solution for this!

1st Step To Digitalisation: Connectivity - Manufacturing Data Collection

In today's competitive production landscape, manufacturing data collection is the key to unlocking efficiency and driving growth. With the increasing complexity of modern production environments, relying on guesswork or outdated methods is no longer an option.

2nd Step To Digitalisation: Manufacturing Data Analytics

Collecting data is just the beginning; the real challenge lies in manufacturing data analytics based on real-time data. Take the 2nd step to digitalisation now!

3rd Step To Digitalisation: Transparency And Collaboration With Real-Time Data In Manufacturing

In the fast-paced world of manufacturing, having access to real-time data in manufacturing is essential for staying ahead of the curve. With constant changes on the shop floor, knowing what’s happening at any given moment can be the difference between meeting your production targets and falling behind.

4th step of digitalisation: Master Predictive Capacity with Production Scheduling Software

By adding new features in every step of the digitalisation process your factory moves towards becoming a Smart Factory. One key milestone in this is to master predictive capacity with Production Scheduling Software - the ability to anticipate what will happen next in the production process.

5th step of Digitalisation - Change The Culture - Become A Smart Factory

The journey towards smart manufacturing is more than just adopting new technologies; it's about integrating various digital layers to create a fully optimised, intelligent factory - A Smart Factory. It’s a culture change in the company of how things are done from here on forward. Each step in the digitalisation process before contributes to moving away from paper and excel towards digitalisation. By combining data collection, manufacturing data analytics and making sense of this real-time data using production scheduling software, you can achieve a seamless, fully digitalised environment.

From Shopfloor to Boardroom: Data-driven decisions in manufacturing

A critical first step in realising Lean Manufacturing, improving OEE, and adopting Industry 4.0 concepts is integrating data-driven strategies from the shop floor to the boardroom manufacturing. This strategy change is a step towards sustainable practices and smart manufacturing, not only an improvement in operations. Explore how the clarity of real-time data may transform your manufacturing operations by reading this article.